The $10k/Hour Breakdown: How Predictive AI Stops Factory Disasters Before They Start

Key Takeaways: Predict & Prevent

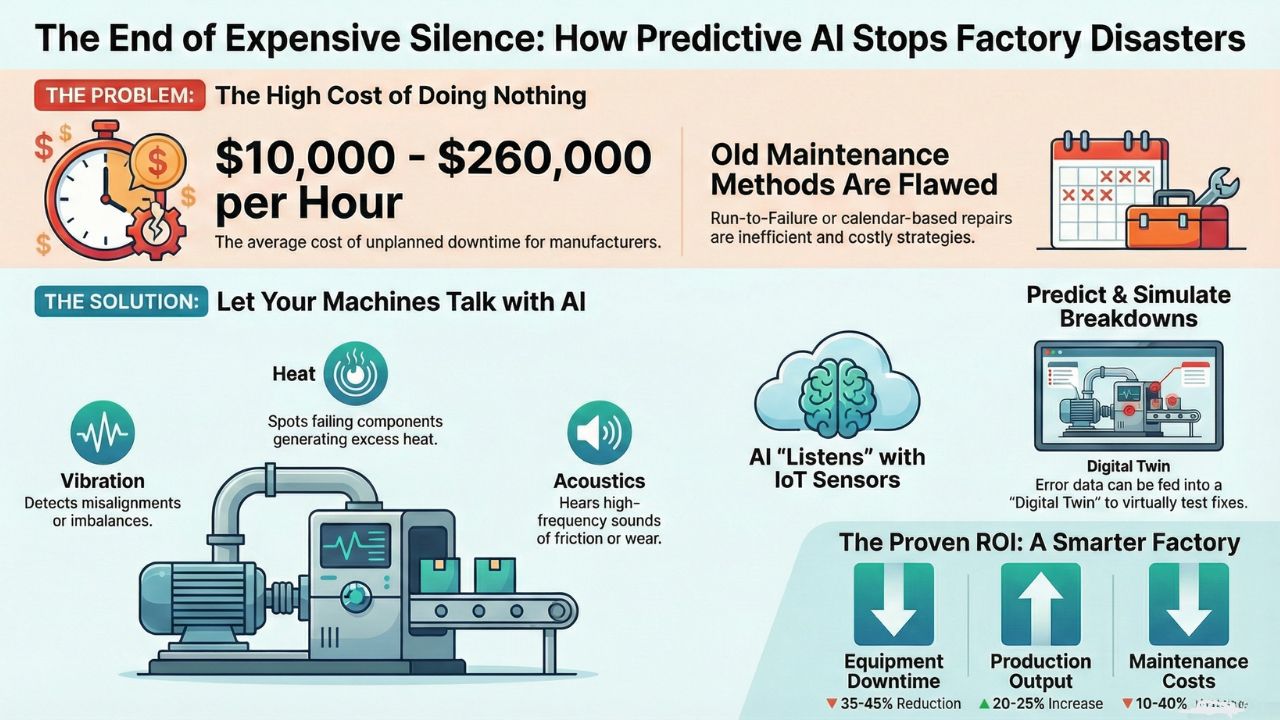

- Silence is Expensive: Unplanned downtime costs manufacturers an average of $10,000 to $260,000 per hour.

- The AI Advantage: Algorithms can detect "invisible" machine faults weeks before a breakdown occurs.

- IoT Sensors: Simple, affordable vibration and heat sensors are the "ears" of your smart factory.

- ROI: Shifting from reactive to predictive maintenance can reduce maintenance costs by up to 30%.

The Sound of Losing Money

The most expensive sound in a factory is silence.

When a critical conveyor belt snaps or a motor burns out, production stops. Workers stand idle. Shipments are delayed.

And your profit margin evaporates by the minute.

In the old model of manufacturing, you fixed things only after they broke.

But in the era of Industry 4.0, waiting for failure is a bankruptcy strategy.

This article dives deep into predictive maintenance AI, a core pillar of our extensive guide on Make in India 2.0: The Blueprint for Building an AI-Powered Smart Factory in 2026.

Here is how you can stop bleeding cash and start predicting the future of your machinery.

Why Reactive Maintenance is Dead?

Traditional maintenance relies on the calendar. You change the oil every three months, regardless of whether the machine needs it.

Or worse, you rely on "Run-to-Failure." You push the machine until it smokes.

Predictive analytics manufacturing changes this dynamic entirely.

Instead of guessing, you use data.

By monitoring real-time conditions, you only service machines when they actually need it.

This maximizes the lifespan of your equipment and eliminates unnecessary labor costs.

How AI "Hears" a Breakdown (The Technology)

How does a computer know a motor is about to fail?

It listens.

AI machine health monitoring relies on a network of industrial IoT sensors attached to your equipment.

These sensors track three critical metrics:

- Vibration Analysis: A misaligned shaft vibrates differently than a healthy one. AI detects these subtle frequency changes long before a human feels a "wobble."

- Thermal Imaging: Failing components generate excess heat. Sensors spot these "hotspots" instantly.

- Acoustics: Friction creates sound. Ultrasonic sensors pick up the high-frequency screech of a drying bearing.

From Detection to Simulation

Once your sensors detect an anomaly, what comes next?

You don't just send a technician in blindly. You test the fix virtually.

Advanced manufacturers are now linking their predictive data to a virtual replica of their plant.

You can feed the error data into a Digital Twin to simulate the breakdown before it happens in the real world.

This allows you to see exactly how a specific part failure will impact the entire production line, helping you prioritize which repairs are urgent and which can wait.

Reducing Factory Downtime: The Numbers

The goal of reducing factory downtime isn't just about convenience; it is about survival.

For an Indian MSME, a single day of downtime can kill a monthly quota.

Implementing predictive maintenance AI typically delivers:

- 35-45% reduction in equipment downtime.

- 20-25% increase in production.

- 10-40% reduction in maintenance costs.

Conclusion: Listen to Your Machines

Your machines are talking to you.

They are telling you they are running hot, that a bearing is loose, or that a belt is fraying.

The only question is: Are you listening?

By installing simple IoT sensors and using AI to interpret the data, you can banish the expensive sound of silence from your factory floor forever.

Frequently Asked Questions (FAQ)

The most effective method is implementing predictive maintenance AI. By using sensors to monitor vibration and temperature, algorithms can alert you to potential failures weeks in advance, allowing you to schedule repairs during planned downtime.

While results vary by industry, reports suggest that shifting from reactive to predictive strategies can save 30% to 40% on maintenance costs and eliminate thousands of dollars in lost production time per hour.

The most common industrial IoT sensors include accelerometers (for vibration), thermocouples (for heat), and ultrasonic microphones (for acoustic anomalies). These are often inexpensive and magnetic, making them easy to retrofit onto old machines.