Make in India 2.0: The Blueprint for Building an AI-Powered Smart Factory in 2026

Key Takeaways: The 2026 Roadmap

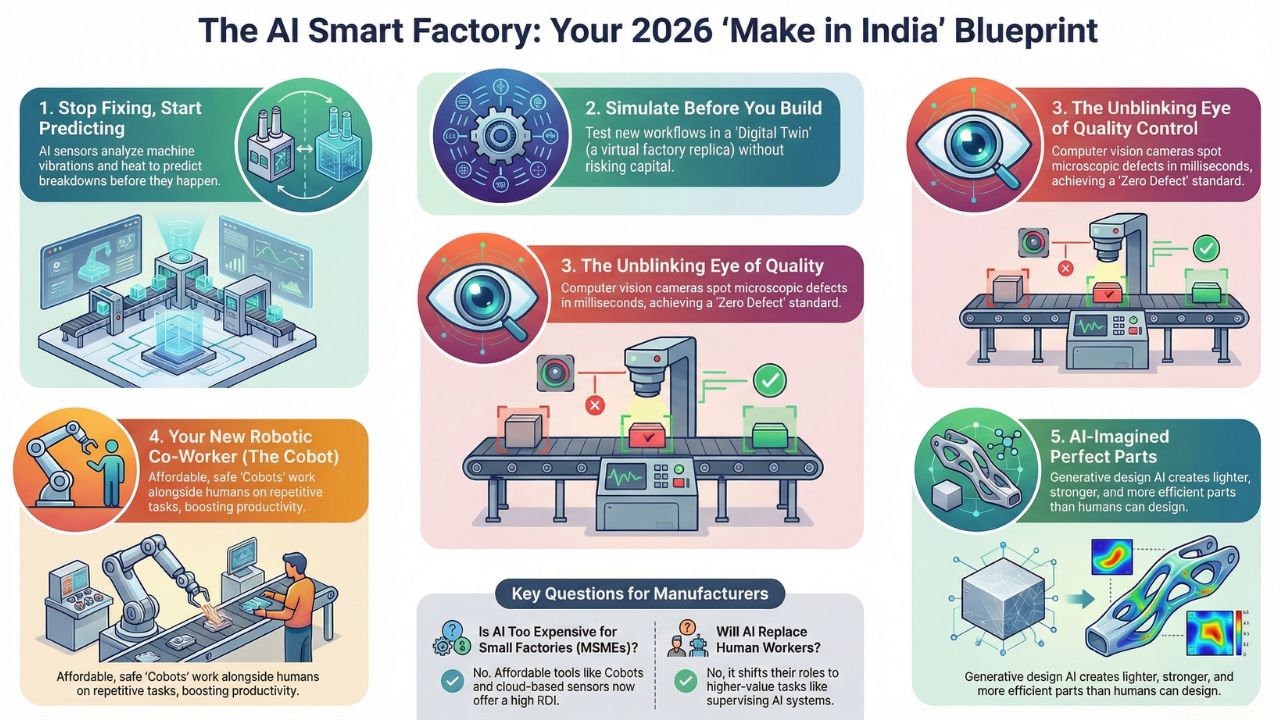

- The Manual Era is Over: Traditional assembly lines are losing to data-driven "Smart Factories."

- Predict & Prevent: AI sensors now predict breakdowns before they stop production.

- Virtual Testing: Digital Twins allow you to simulate factory changes without risking a rupee.

- Affordable Automation: Cobots are making robotics accessible even for Indian MSMEs.

- Zero Defects: Computer vision systems are achieving quality standards human inspectors can’t match.

The factory floor is changing. For decades, Make in India meant maximizing labor and optimizing supply chains.

But as we approach 2026, the rules are being rewritten by Artificial Intelligence.

The manual factory is dead. In its place rises Smart Manufacturing India, a revolution where data turns chaos into profit.

This isn't just about replacing workers with robots. It is about empowering Indian manufacturers, from agile MSMEs to industrial giants, to compete on a global stage using Industry 4.0 AI tools.

If you are still relying on reactive repairs and manual inspections, you are already losing money. Here is your blueprint to modernizing your production line.

1. Stop Fixing, Start Predicting (Predictive Maintenance)

Imagine knowing a machine will fail three weeks before it actually does. That is the power of AI machine health monitoring.

In a traditional setup, you run a machine until it breaks. Then, production halts, workers stand idle, and you scramble for parts.

Predictive maintenance AI changes the game. By using simple industrial IoT sensors, algorithms analyze vibration and heat patterns to predict failures.

This shifts your factory from "repair mode" to "optimization mode."

Read More: The $10k/Hour Breakdown: How Predictive AI Stops Factory Disasters Before They Start

2. The Industrial Metaverse: Simulate Before You Build

Why risk real capital on a guess? In the past, changing an assembly line meant shutting it down and hoping the new layout worked.

Today, CEOs are running simulations in the "Industrial Metaverse" using Digital Twin technology manufacturing.

A Digital Twin is an exact virtual replica of your physical factory. You can test new workflows, train AI models, and stress-test supply chains in a safe, virtual environment.

If it works in the simulation, it will work on the floor.

Read More: Clone Your Factory: Why CEOs Are Running Simulations in the "Industrial Metaverse"

3. The Unblinking Eye of Quality Control

Human inspectors are incredible, but they get tired. They blink. They miss things. Computer vision quality control systems do not.

Modern automated visual inspection cameras can spot microscopic cracks, paint defects, and misalignment in milliseconds.

For Indian exporters, this is the key to achieving the "Zero Defect" standard required by global markets. These systems ensure that every single unit leaving your factory is perfect, protecting your brand reputation.

Read More: The Unblinking Eye: Why AI Cameras Are Beating Human Inspectors at Quality Control

4. Meet Your New Co-Worker: The Cobot

Robots used to be dangerous giants trapped behind safety cages. Enter the Collaborative Robot (Cobot).

These are smaller, safer, and smarter robots designed to work alongside humans, not replace them. For AI for MSME manufacturing, Cobots are a game-changer.

They are easy to program, affordable, and can handle repetitive tasks like pick-and-place or screw driving. This allows your human workforce to focus on high-value tasks that require creativity and problem-solving.

Read More: Meet Your New Co-Worker: Why Cobots Are Saving Jobs, Not Stealing Them

5. Alien Engineering: Designing with Generative AI

What if your software could invent parts you never thought of? Generative design software uses AI to explore thousands of design permutations.

You tell the AI the goals (weight, load capacity, material) and it generates the optimal geometry.

The results often look "alien", organic, bone-like structures that are lighter yet stronger than human designs. This reduces material costs and results in better performing products.

Read More: Alien Engineering: How Generative AI Designs Parts Humans Can't Imagine

The Road to 2026

The transition to factory automation 2026 is not an option; it is a necessity.

Adopting a Make in India AI roadmap allows manufacturers to cut waste, boost safety, and increase margins.

The technology is ready. The tools are accessible. The only question remaining is: Is your factory ready to get smart?

Frequently Asked Questions (FAQ)

Not anymore. Tools like Cobots and cloud-based predictive maintenance sensors have dropped significantly in price, offering a high ROI for small factories.

It shifts their roles. Instead of dangerous, repetitive labor, workers become operators and supervisors of AI systems, often leading to upskilling and higher wages.

Start small. Implement sensors on your most critical machine (Predictive Maintenance) or deploy one Cobot for a repetitive task. Scale up as you see results.