Alien Engineering: How Generative AI Designs Parts Humans Can't Imagine

Key Takeaways: The AI Engineer

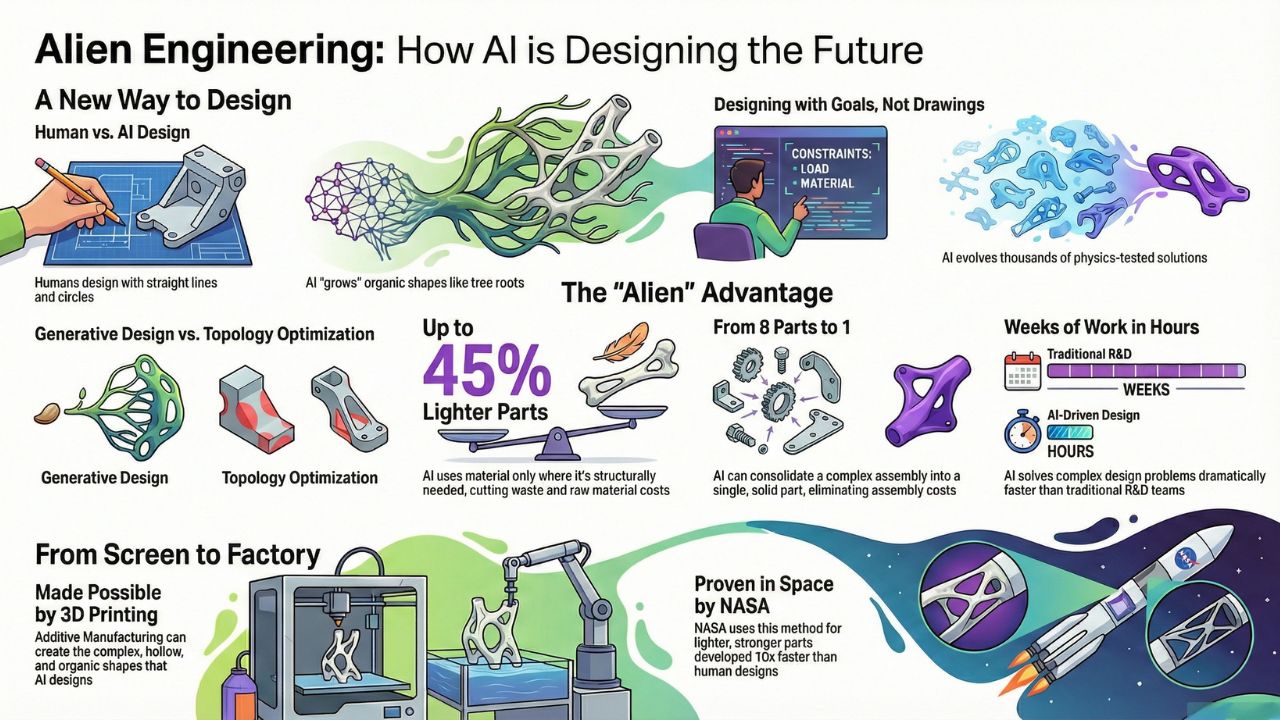

- Beyond Human Logic: AI explores thousands of design options in minutes, often creating "organic" shapes humans would never conceive.

- Material Savings: Generative designs use material only where structurally necessary, reducing weight by up to 45%.

- Topology Optimization: A process that shaves "fat" off existing designs to leave only the bone-like load-bearing structure.

- Faster to Market: What used to take design teams weeks of iteration can now be solved by algorithms in hours.

Designing with an Alien Mind

If you ask a human engineer to design a bracket, they will draw straight lines and perfect circles.

If you ask an AI, it will grow a shape that looks like a human bone or a tree root.

This is generative design, and it is changing the fundamental physics of manufacturing.

Instead of drawing a part, you tell the AI the goals (weight, load capacity, material) and the constraints (bolt holes, manufacturing method).

The AI then evolves thousands of solutions, testing each one against the laws of physics.

This article concludes our extensive guide on Make in India 2.0: The Blueprint for Building an AI-Powered Smart Factory in 2026.

Here is how to harness "alien engineering" for your factory.

Generative Design vs. Topology Optimization

These terms are often used interchangeably, but they are different tools.

Topology optimization is like a sculptor with a block of stone.

You start with a working design, and the software removes material that isn't carrying a load.

It "lightweights" a part, often reducing mass by 30-50% while maintaining strength.

Generative design is like a farmer growing a plant. You don't start with a design;

you start with empty space and goals. The AI grows the part from scratch, often finding solutions no human could imagine.

Why "Alien" Shapes are Better?

Why do these parts look so strange?

Because nature is the ultimate engineer.

Trees and bones are optimized to be as strong as possible using the least amount of material.

Generative AI mimics this biological evolution.

For manufacturers, this "biomimicry" means:

- Less Raw Material: You stop paying for waste.

- Lighter Products: A lighter car burns less fuel; a lighter drone flies longer.

- Part Consolidation: An assembly of 8 different parts can often be generated as a single, solid component, eliminating assembly costs entirely.

From Screen to Reality: Manufacturing the Impossible

For a long time, these designs were trapped on computer screens because they were too complex to machine.

You couldn't mill a hollow, organic bone shape.

But with the rise of Additive Manufacturing (3D Printing), these alien shapes are now printable in metal.

You can design the part here, then stress-test it in your Digital Twin to ensure it holds up before you ever print a single unit.

Case Study: NASA’s "Evolved" Structures

If it works in space, it works in your factory.

NASA uses generative design to create "evolved structures" for space telescopes and landers.

By letting AI design the mounts, they created parts that were 10x faster to develop and significantly lighter than human designs.

For an Indian MSME, the stakes might not be intergalactic, but the cost savings on material and shipping are just as real.

Conclusion: The Algorithm is Your Best Engineer

The engineers of 2026 will not just be drawing parts; they will be "co-creating" with algorithms.

By adopting generative design software like Autodesk Fusion 360, you can reduce your material costs, speed up R&D, and create products that are lighter and stronger than your competition.

The future of engineering looks alien. And that is a good thing.

Frequently Asked Questions (FAQ)

By placing material only where it is structurally needed to handle specific loads, generative design often reduces the total mass of a part by 40% or more.

This directly lowers the cost of raw materials (like titanium or aluminum) per unit.

Yes. AI-driven generative design software can create complex mechanical parts like brackets, heat exchangers, and even entire chassis components.

It validates these designs against stress and fatigue constraints automatically.

Topology optimization is a mathematical method that optimizes material distribution within a given design space.

It essentially "trims the fat" from an existing design to maximize performance (like stiffness) while minimizing weight.