Meet Your New Co-Worker: Why Cobots Are Saving Jobs, Not Stealing Them

Key Takeaways: The Collaborative Revolution

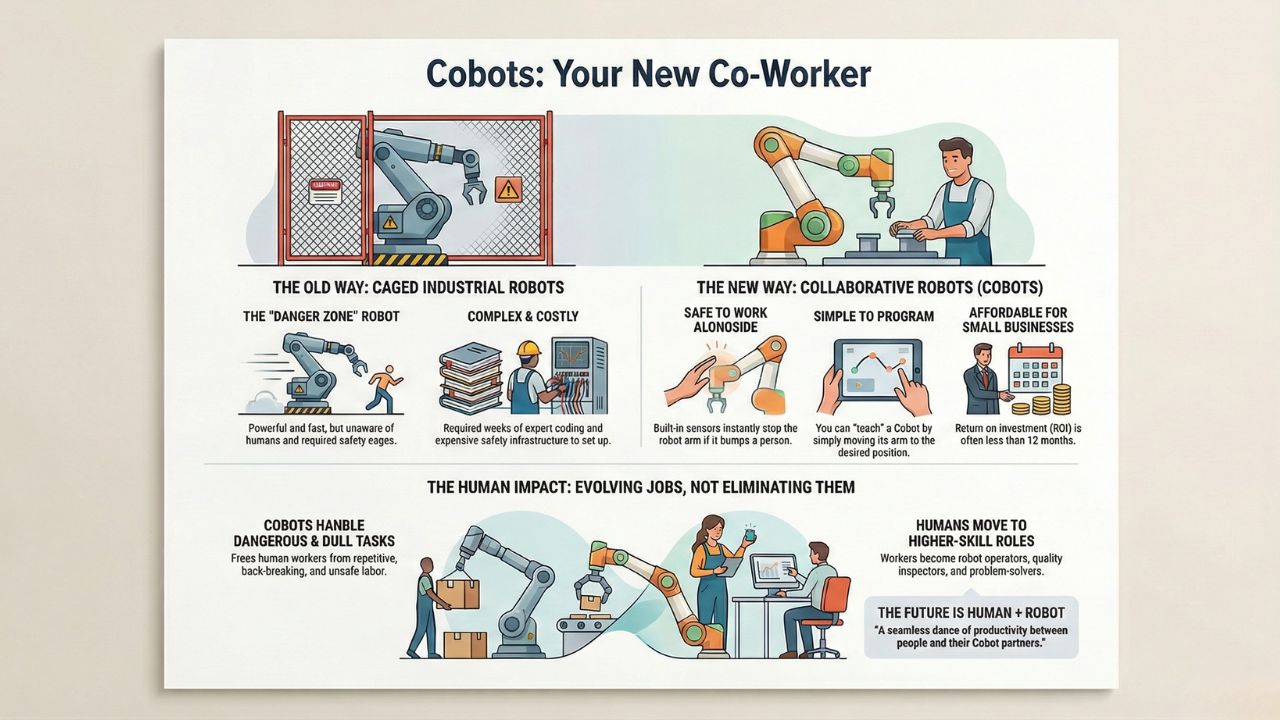

- No Cages Required: Unlike traditional industrial robots, Cobots are designed to work safely alongside humans.

- Affordable Automation: With rapid ROI, Cobots are now accessible to Indian MSMEs, not just auto giants.

- Easy Programming: If you can use a smartphone, you can likely program a modern Cobot.

- Job Evolution: They take over the dangerous, dull tasks, freeing humans for skilled work.

The End of the "Danger Zone"

For decades, industrial robots were powerful but dumb.

They were kept in cages because if a human walked into their path, the robot wouldn't stop.

That era is ending. Enter the Collaborative Robot (Cobot).

These are not the job-stealing terminators of science fiction. They are smart, sensitive tools designed to assist your workforce, not replace it.

This deep dive is a vital part of our extensive guide on Make in India 2.0: The Blueprint for Building an AI-Powered Smart Factory in 2026.

Here is why your next hire should be made of metal and silicon.

Cobots vs. Industrial Robots: What’s the Difference?

Think of a traditional robot as a wild tiger: powerful, but it needs to be behind bars.

Think of a Cobot as a trained guide dog: helpful, safe, and responsive.

Cobots vs industrial robots differ in three main ways:

- Safety: Cobots have built-in force sensors. If they bump into a human, they stop instantly.

- Footprint: They are small and lightweight. You can mount them on a table or move them between stations.

- Setup: Traditional robots require weeks of coding. Cobots can be "taught" by simply moving their arm to the desired position.

Safety First: How Human-Robot Collaboration Works?

Is it safe to stand next to a moving robot arm? With collaborative robots in India, the answer is yes.

Advanced torque sensors monitor every joint.

If the robot encounters resistance, like a human hand blocking its path, it freezes in milliseconds.

This allows for true human-robot collaboration.

A human can place a part, the Cobot can screw it in, and the human can remove it.

A seamless dance of productivity.

Why MSMEs Can Finally Afford Automation?

The biggest myth is that robotics is only for billionaires.

SME robotics automation is booming because the cost of entry has plummeted.

You no longer need to build a safety cage or hire an expensive integration team.

Because they are plug-and-play, the Return on Investment (ROI) for a Cobot is often less than 12 months.

For a small factory in Pune or Chennai, this levels the playing field against global competitors.

Maintaining Your Metal Employee

Just like human employees need breaks, Cobots need care.

While they don't take sick days, their joints and motors do wear down over time.

To ensure they never stop working, smart factories connect them to a predictive maintenance grid.

This allows the Cobot to self-diagnose and alert you before a joint fail, ensuring 24/7 uptime.

Conclusion: Saving Jobs by changing them

History shows that automation increases productivity, which increases demand, which creates jobs.

By handing over the repetitive, back-breaking work to Cobots, you protect your workers from injury.

You free them to become robot operators, quality inspectors, and problem solvers.

The future isn't Human vs. Robot. It's Human + Robot.

Frequently Asked Questions (FAQ)

A traditional robot is designed to operate autonomously and usually requires safety cages to protect humans.

A Cobot (Collaborative Robot) is designed with sensors to work safely in close proximity to humans, slowing down or stopping upon contact.

Yes, if it is a certified Cobot. They are equipped with power and force limiting technology (PFL) that ensures they stop immediately if they touch a person or object, making them safe for uncaged environments.

Absolutely. Cobots are significantly cheaper than traditional industrial robots and require no expensive safety infrastructure.

Their flexibility allows MSMEs to use them for high-mix, low-volume production runs effectively.