Clone Your Factory: Why CEOs Are Running Simulations in the "Industrial Metaverse"

Key Takeaways: The Industrial Metaverse

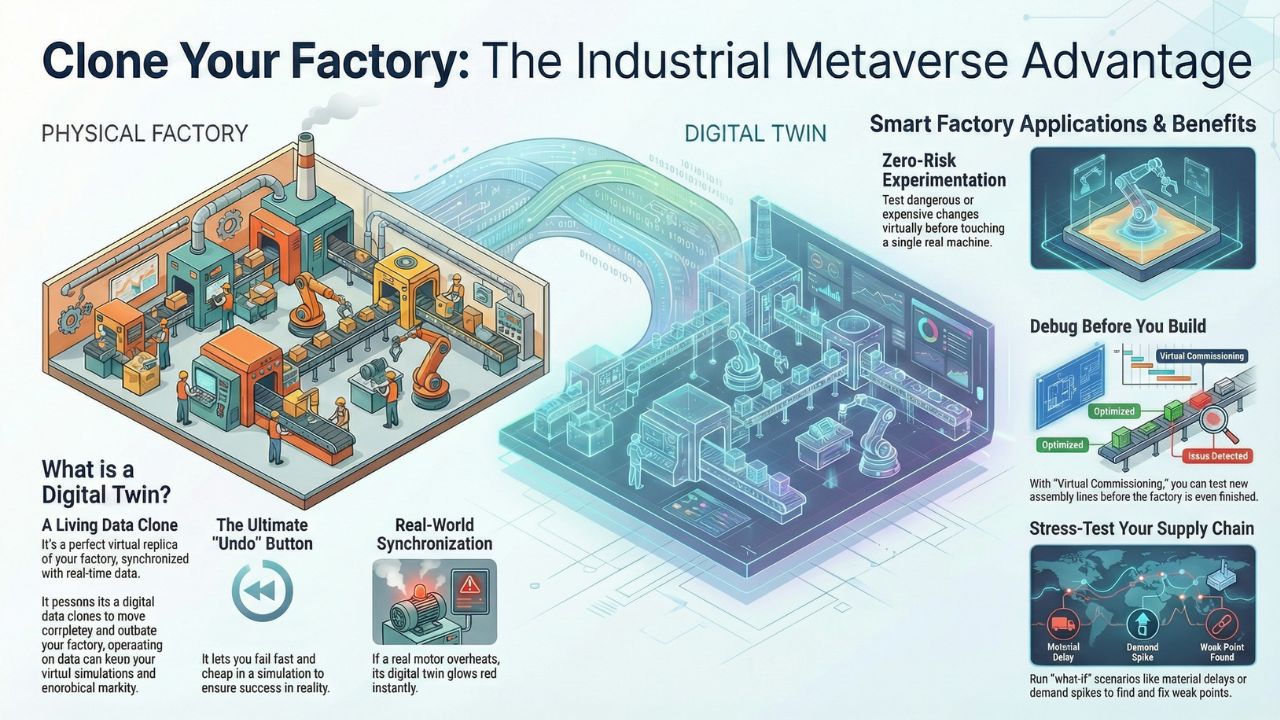

- Zero Risk: Test dangerous or expensive changes virtually before touching a single real machine.

- The Digital Twin: A real-time, mathematically perfect virtual replica of your physical factory.

- Virtual Commissioning: Debug your assembly line code in the software, not on the floor.

- Efficiency: Identify bottlenecks in your supply chain instantly using factory simulation software.

The Ultimate "Undo" Button

Imagine building a new assembly line, turning it on, and realizing the robots are crashing into each other.

In the physical world, that mistake costs millions of rupees and weeks of downtime.

In the Industrial Metaverse, you just hit "Undo."

This is the power of Digital Twin technology manufacturing. It allows you to fail fast, fail cheap, and fail virtually, so you can succeed in reality.

This deep dive is a critical part of our extensive guide on Make in India 2.0: The Blueprint for Building an AI-Powered Smart Factory in 2026.

Here is why smart CEOs are moving their operations into the virtual world.

What is a Digital Twin?

A Digital Twin is not just a 3D model. It is a living, breathing data clone.

It connects your physical machines to a virtual environment using real-time data.

If a motor overheats in your real factory, the motor in your Digital Twin glows red.

This synchronization allows you to monitor operations remotely and, more importantly, predict the future.

Virtual Commissioning: The New Standard

Historically, "commissioning" (setting up new equipment) was the most stressful part of manufacturing.

Engineers would hold their breath as they powered up a new line, hoping the code was correct.

With virtual commissioning AI, you can run the entire factory in a simulation months before the physical building is even finished.

You can debug the software, train the robots, and optimize the workflow in a computer.

By the time the real machines arrive, you simply plug them in. They work perfectly on Day 1.

Stress-Testing Your Supply Chain

It is not just about machines; it is about logistics.

What happens if your raw material delivery is delayed by 48 hours? What if demand spikes by 200%?

You can’t test this in real life without causing chaos.

In the Industrial Metaverse, you can run "What-If" scenarios. You can simulate supply shocks to see where your system breaks, then reinforce those weak points.

From Design to Destruction (Virtually)

The synergy between design and simulation is where the real magic happens.

You don't just test the factory; you test the product.

For example, you can take a new component and use the twin to test parts designed by Generative AI.

You can virtually stress-test that "alien" looking part to see if it withstands the assembly process, ensuring seamless integration before you pay for the mold.

Conclusion: The Metaverse is for Profit, Not Play

While the consumer world debates the future of VR headsets, the manufacturing world has already moved on.

NVIDIA Omniverse manufacturing and similar platforms are already saving companies billions.

The Industrial Metaverse is real. It is here.

And it is the only way to ensure your factory is optimized, resilient, and ready for 2026.

Frequently Asked Questions (FAQ)

A Digital Twin is a virtual replica of a physical product, process, or system.

It uses real-time data and machine learning to simulate performance, allowing manufacturers to predict issues and optimize operations without physical intervention.

By using factory simulation software, you can apply changes to your Digital Twin first.

You can test new speeds, layouts, or workflows in the simulation.

Once the data proves it works, you implement it on the real line with confidence.

Yes. Major corporations like BMW and Siemens are already using platforms like NVIDIA Omniverse to design and operate factories.

It is a proven technology that bridges the gap between digital data and physical reality.