The Unblinking Eye: Why AI Cameras Are Beating Human Inspectors at Quality Control

Key Takeaways: Zero Defect Manufacturing

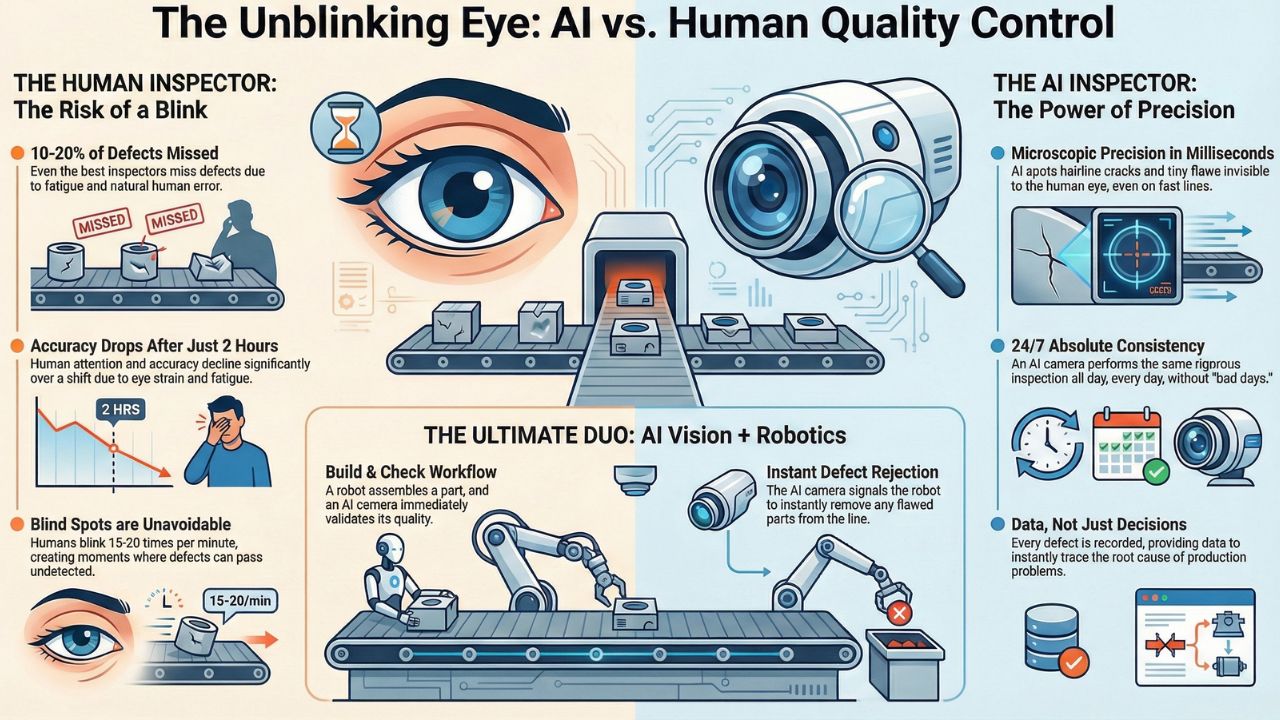

- The Human Limit: Even the best inspectors miss 10-20% of defects due to fatigue.

- Microscopic Precision: Machine vision systems can spot hairline cracks invisible to the naked eye.

- Speed: AI cameras scan products on high-speed conveyor belts in milliseconds.

- Data, Not Just Decisions: Every defect is recorded, helping you trace the root cause instantly.

The Cost of a Blink

A human inspector blinks 15 to 20 times a minute. That is 15 to 20 moments where your product, and your reputation, is flying blind.

In the high-stakes world of manufacturing, a single missed defect can lead to a million-dollar recall. This article explores why automated visual inspection is becoming the global standard.

It is a critical component of our extensive guide on Make in India 2.0: The Blueprint for Building an AI-Powered Smart Factory in 2026.

Here is why relying on human vision is a risk you can no longer afford.

Why Humans Fail (It’s Biology, Not Laziness)?

Humans are incredible, but we are not machines. We get tired. We get distracted. Our eyes strain under harsh factory lighting.

Studies show that after just two hours, a human inspector’s accuracy drops significantly. Computer vision quality control eliminates this biological variable.

An AI camera does not have "bad days." It does not get bored. It provides the same rigorous inspection at 5:00 PM as it did at 9:00 AM, ensuring absolute consistency.

How AI "See" Differently?

Machine vision systems in India are moving beyond simple "Pass/Fail" sensors. They use Deep Learning.

You train the AI by showing it thousands of images of "good" products and "bad" products. Over time, the algorithm learns to detect:

- Surface Defects: Scratches, dents, or paint bubbles.

- Dimensional Accuracy: Measuring parts to the micron.

- Missing Components: ensuring every screw and label is present.

The Ultimate Duo: Cobots + Vision

The real power unlocks when you combine eyes with hands. Imagine a workflow where a robot assembles a part, and an AI camera immediately validates it.

This is the future of the assembly line: The robot builds it, and the AI camera checks it. If the camera spots a defect, it signals the robot to reject the part instantly.

This prevents bad parts from moving down the line, saving value-added time and materials.

Achieving "Zero Defect" Manufacturing

For Indian exporters, the "Zero Defect" standard is often the barrier to entry for Western markets. Global buyers demand perfection.

Implementing AI defect detection is the only way to guarantee 100% compliance. It transforms your quality control from a "sampling" process (checking 1 in 100) to a "total" process (checking every single unit).

Conclusion: Trust the Algorithm

Your customers do not care if your inspector was tired. They only care that the product works. Switching to automated inspection is not just about cutting labor costs.

It is about buying insurance for your brand reputation. In 2026, the factories that win will be the ones that never blink.

Frequently Asked Questions (FAQ)

Yes. AI systems are consistent, faster, and capable of detecting microscopic defects that the human eye cannot physically see. They maintain 100% attention rates throughout a shift, whereas human attention naturally degrades.

Implementation involves installing high-resolution industrial cameras above the belt and connecting them to an edge computing device running AI software. The system triggers a pneumatic arm or air blast to divert defective items automatically.

While initial setup costs for hardware (cameras, lighting) and software exist, the ROI is typically realized within 12-18 months through reduced labor costs, fewer returns, and the elimination of expensive recalls.